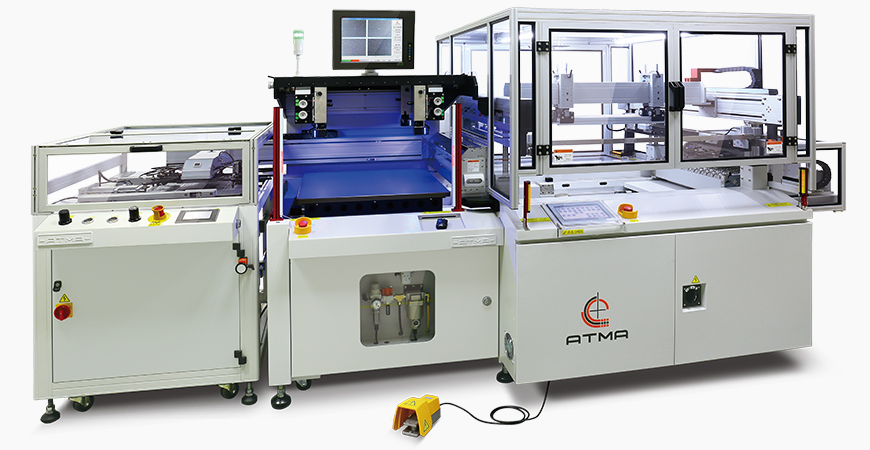

ATMA

ATMATIC MF66/F

Screen Printers

FEATURES

Registration Pin Alignment : substrates are piled up within area of registration pins, vacuum carrier picks up the substrate sequence

Infeed Vacuum Carrier : adopts multi-layer vacuum cup (Viton Fluoro rubber), increase vacuum cups up to 10 sets, maximum suction area 650x650 mm

Upgrade Precision : registration platform is adopted three sets of servo motor to control X/X/Y direction, used by visual system to judge table displacement volume, sliding table reciprocates right / left positioning, adopts hydraulic buffer + electromagnetic suction to attain registration accuracy within 5µm.

Printing Uniform Layer Thickness : squeegee / flood coater is adopted guide rail cylinder to raise precise linear motion, leading accurate direction and smooth to facilitate the equalized air pressure to render completely onto substrate, assure printing uniform layer thickness and consistency

Servo Motor Straight-drive : none malfunction, solid printing torque, fully digital control, full stroke extreme stable speed motion.

Equalized Air Pressure Control : squeegee / flood coater digital equalized air pressure system control, enable to preset air pressure individually on HMI (3~62 kgf)

Safety Protection : error diagnosis interlocking loop, error message indication, mono key auto safety restoration loop, safety light barrier, E-stop switch, warning lamp etccomprehensive safety protection.